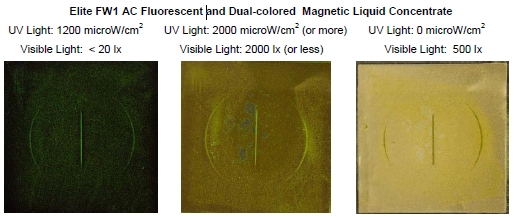

4. Recommended procedure for Fluorescent and Dual-colored Magnetic Powder Elite FW1AC use in undarkened area (visible light >20 lx) according to ASME V Art.7 Appendix III; ASTM E 709; ISO 9934-1 and other applicable Standards

Essential Variables:

- Particle manufacturer and designation: NDT ITALIANA Srl / Elite FW1 AC

- Minimum UV Light Intensity: 20W/m2 ( 2000 microW/cm2)

- Maximum Visible Light Intensity: 2000 lx

(Visible light intensity recommended in case of very small indications:

250-350 lx.)

According to the results of the test, illustrated under the set of photos, the indications under the proposed conditions appear the same or better than obtained under standard conditions.

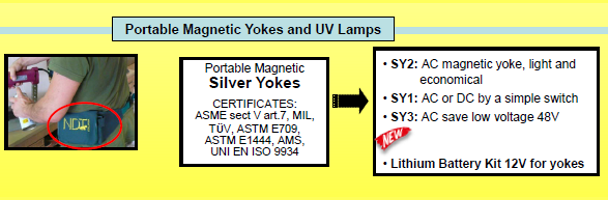

The Magnetic Yokes are rugged high performance instruments designed for Magnetic Particle inspection according to accepted Nondestructive testing standards. Certain operating procedures and safety precautions should be observed. All our magnetic yokes are certified according to the following Standards: EN ISO 9934, ASTM E1444, ASTM E709, ASTM E3024, ASME V Art. 7.

INSTRUMENT DESCRIPTION:

Basically, a Yoke is an electromagnet producing a strong magnetic field.

Placement of the two poles (legs) upon ferrous metal provides a path for the intense magnetic field to pass from one pole to the other. The part completes the flux path and becomes highly magnetized.

Electronic circuitry contained within the rugged molded housing of the SY1 permits selection of a strong constant AC field, or high intensity pulsed DC field. Flexibility of the legs permit the field to be ÔÇťfocusedÔÇŁ at the precise area of inspection. All yokes can be used with magnetic dry powder, wet fluorescent or visible

.

12.142 BAT LITHIUM BATTERY KIT FOR INVERTER

New lithium battery kit that allows the use of the magnetic yoke everywhere with no wires!

12.142 INV PORTABLE YOKE INVERTER DC / AC

It allows to magnetize both in DC and AC!

1st yoke in the world lithium battery powered working DC and AC!

Highest portability: no wires linked to mains

Lightweight battery: only 800 grams (28 oz) in shoulder bag (included)

Voltage: 12V

Capacity: 9 A/h allows for an use of up to 4 hours (50% duty cycle) in AC

and up to 8 hours (50% duty cycle) in DC.

Battery charger included.

Dimensions: 260 x 130 x 110 mm (10 x 5 x 4,5 in)